GICON-SOF

GICON® provides design services for foundation structures in the field of offshore wind energy. The focus is on the research project GICON® SOF, which is funded by the state of Mecklenburg-Vorpommern and aims to build the first floating foundation with an offshore wind turbine of the 2 MW class in Germany

With the help of professional software support, the Wind Engineering department carries out all planning services from basic engineering to Basis of Design, thus creating the foundations for further planning of the detailed design. The department also coordinates other services required by other departments for the project, such as planning services for the subsoil, concrete construction, approval procedures or ecological issues.

Planning services for offshore structures

- project management for research projects

- Engineering services for Basis of Design

- Basic engineering services

Further Information

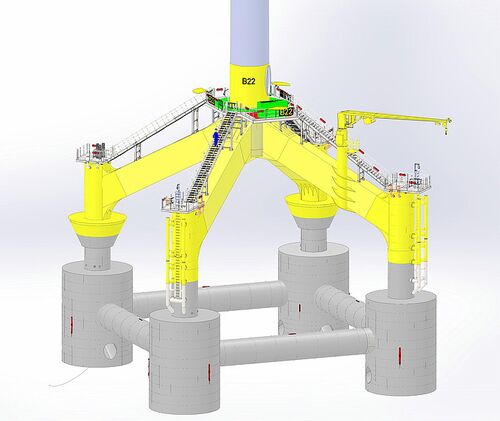

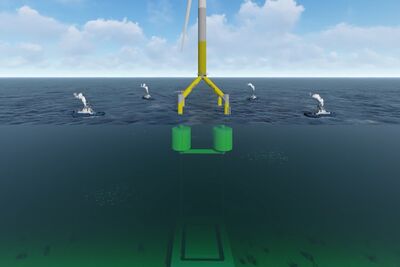

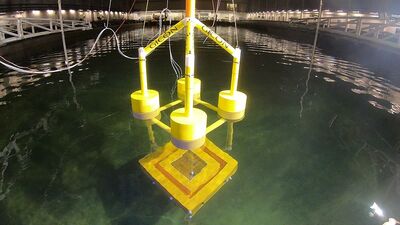

As a tension-leg platform (TLP), the GICON® SOF has enormous advantages over other floating substructures such as the semi-submersible (semi-sub) or the spar concept. Unlike semi-submersibles and spars, which use slack anchor cables, the TLP uses prestressed anchor cables. The TLP has, due to the use of large floating bodies, a large buoyancy excess which causes an upward force. The tightly tensioned anchor cables pull the TLP underwater, providing very stiff bracing to the structure. Even in the most adverse weather conditions, the system remains stable and only very small movements and accelerations occur. Due to the inherent stability of the TLP, it can be constructed much slimmer than a semi-submersible or spar.

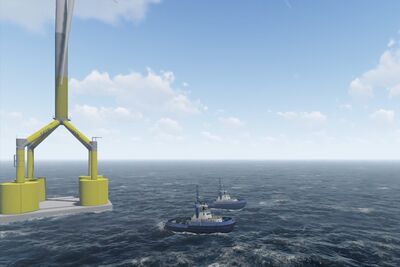

By using the GICON® SOF in areas with high wind availability at water depths of 45 to 350 meters and more, higher revenues can be generated than with fixed foundations.

A standardized foundation design can be used per site, which reduces manufacturing costs. Water depth differences are compensated for by the cable lengths alone, while the SOF design remains the same regardless of water depth.

The foundation is manufactured and the turbine is assembled in a shipyard or harbor, making it weather-independent. The structure, including the turbine, is self-floating and only needs to be towed to the installation site. Thus, no expensive erection ships or jack-up platforms are required for installation. If the structures are no longer needed one day, dismantling them at the end of their service life is comparatively easy.

The foundation is completely replaceable if required. Maintenance work can be carried out cost-effectively at a shipyard or in port.

An independent consulting institute calculated a levelized cost of energy of 5 - 8 ct/kWh for the optimized design of the GICON® SOF for a wind farm with 80 wind turbines of 6 MW each at 80 m water depth and 50 km distance to the mainland. The use in greater water depths as well as existing optimization potentials will reduce these costs even further.

During the construction of offshore wind turbines, driving the foundations into the seabed usually generates sound waves that can injure the hearing of marine life and cause behavioral changes. By not ramming into the seabed, TLP is setting an example in terms of environmental protection and CO2 reduction.