Biosolar – Microalgae project solutions from a single source

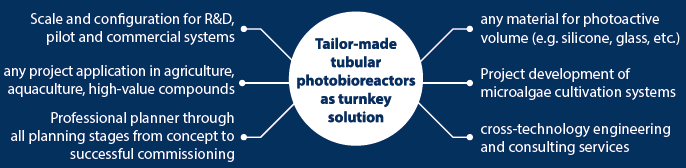

We offer complete services – technology agnostic and as turnkey solutions.

As an independent engineering service provider, we offer our customers the entire range from engineering and consulting services to system delivery, as well as support during all phases of the implementation of microalgae projects – from plant design to commissioning of the cultivation systems.

Consulting services

- Process development of algae cultivation concepts

- Technology development and efficiency enhancement

- Tailor-made process concepts

- Repowering of existing microalgae cultivation systems

- Integration of microalgal cultivation systems, e. g.

- Coupled temperature management of microalgae culture

- Use of alternative substrates from fluid and gaseous by-product streams

- Operational management of microalgal systems

- Application concepts for and integration of microalgae…

- … for food and feed purposes

- … in aquaculture

- … for soil improvement

- … to produce high-value compounds

- … and many more

Engineering Services

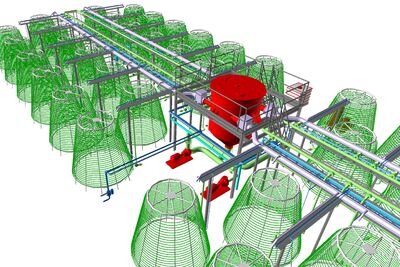

- Technology-agnostic project development of microalgae cultivation systems as stand-alone or incorporated units

- All planning stages for complete or partial systems for commercial scale production as newly built systems, conversion, and expansion

- Process engineering for pilot plants for R&D tasks with instrumentation and control equipment according to customer requirements

- Stand-alone small-scale systems for agriculture and aquaculture with integration to existing infrastructure and bio processes

- Coupled plants for algae technology and biogas production using the biorefinery principle

- Tailor-made concepts according to customer requirements

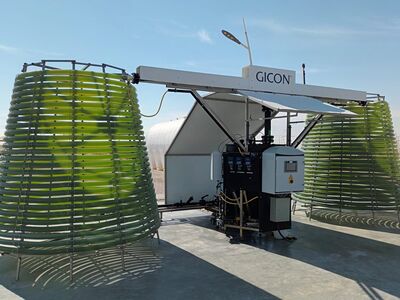

GICON® engineers have planned a broad variety of photobioreactor plants ranging from R&D to commercial-scale systems for 25 years.

Europe’s largest photobioreactor system (700 m3) made of glass tubes in Klötze/Germany was designed by GICON® engineers.

We offer engineering services and plant delivery, as well as support for all phases of the implementation of microalgae projects - from concept development to commissioning of the plants.

We have compiled a detailed overview of our topics and services in four different flyers (PDF):

- Microalgae Technology - Consulting and Engineering

- Algae in Aquaculture - Planing Consulting Construction

- GICON®-Photobioreactor - Innovative Technology for the Cultivation of Microalgae

- GICON®-Photobioreactor - Portfolio

- GICON® References in Microalgae Photobioreactor Technology

The GICON® photobioreactor technology

The GICON® photobioreactor (PBR) is designed as a flexible base module for the stable cultivation of microalgae with defined and high product quality and modular integration in a variety of bio-based processes.

- Small-scale systems in modular arrangement up to 25,000 litres

- Tailor-made commercial production systems as turnkey solutions

Some outstanding features of the GICON® PBR:

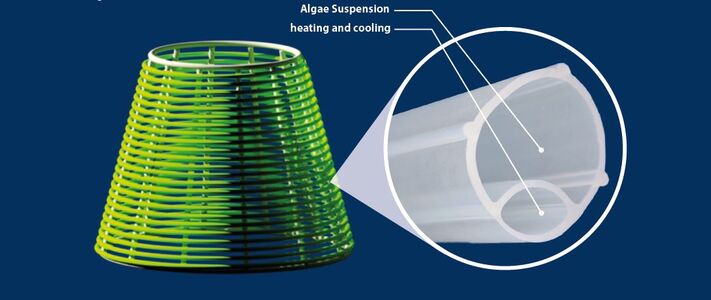

- Integrated closed-loop temperature control using innovative double chamber tubing system for ideal cultivation parameters (resource-conserving water use, any kind of heating and cooling source, no greenhouse necessary)

- No couplings required

- Easy to integrate in coupling processes at upstream and downstream level

- Available as ready-to-operate system solutions based on the GICON®-PBR

- Tailor-made process control including fully automated temperature control

- Simple operation through touch-screen interface and on request with remote-access

- Optimal light availability adapted to the location and the day

- Energy-saving operation through pulse technology

- High chemical resistance to high salt concentrations and relevant pH values

- Food-compatible (FDA-approved), chemically stable material with reduced formation of organic deposits and UV stability

Algae can be cultivated in fresh, brackish water or saltwater. They are characterized by a low land requirement and low water consumption. Areas usable for food production are not occupied.

Microalgae use CO2 as a carbon source and produce oxygen and biomass.

Microalgae convert absorbed solar energy into biomass five- to ten-times better compared to terrestrial plants. Thus, microalgae get more out of the sun and grow more efficiently.

Microalgae have a high protein and lipid content and possess a wealth of valuable ingredients such as pigments, carotenoids, vitamins, essential fatty acids and much more. They thus prove to be multi-talents with enormous application potential.

A stable and resource-saving production of microalgae biomass requires a cultivation system with a high degree of effectiveness and controllability. Process control within the ideal growth range of the microalgae requires gentle temperature control with an effective supply of sunlight. The innovative GICON® PBR, based on the Christmas tree principle, combines for the first time the main requirements of photobioreactor systems for stable growth yields.

For this achievement, the photobioreactor was awarded "Innovation of the Month" (May 2012) by the German Center for Research & Innovation in New York.

The GICON® PBR is designed for use as a stand-alone small plant, as a pilot plant for research and development, and as a basic module for large-scale industrial plants. By combining individual modules, reactor systems of any scale are achieveable. The systems are tailor-made to meet the client's requirements. Thus, they guarantee a continuous production of high-quality, defined algae biomass.

At the core of the GICON® Photobioreactor is the flexible, tubular silicone-based tube system. It is the result of the successful cooperation between GICON® and Wacker Chemie AG. The novel, geometrically variable design of the double chamber system protects the algae from extreme temperature fluctuations. Thus, a precisely fitting temperature control of the cultures can be achieved. The silicone material employed significantly reduces the adhesion of microalgae to the reactor wall – also known as biofouling.

At the same time, tests have shown that the biomass produced is of a quality suitable for use in food and animal feed. Due to the outstanding advantages of the newly-developed system and the transport-friendly properties, the reactor can be used for the cultivation of photoactive microorganisms worldwide; regardless of temperatures and environmental conditions.

Our performance aspiration - A good solution for you!

P: +49 151 406 302 43