Geotechnical Engineering & Post-Mine

The Department of Geotechnical Engineering & Post-Mine has experienced geotechnical specialists who deal with complex tasks in the following areas:

- active mining

- Old mining and remediation mining

- Mining sequence / reuse and tipping

The clientele for our services mainly consists of energy companies, mining companies, stone and earth companies and public clients. For these we develop holistic solutions, starting with an exploration concept up to the ground investigation and subsequent stability assessment including variant investigation for necessary security or underground improvement measures.

After completion of all preliminary examinations, the department takes over the execution planning, the preparation of the tender documents and technical support for the construction work as well as the aftercare. GICON employees have extensive specialist knowledge in the final design and securing of open-cast mine holes and tilted slope systems.

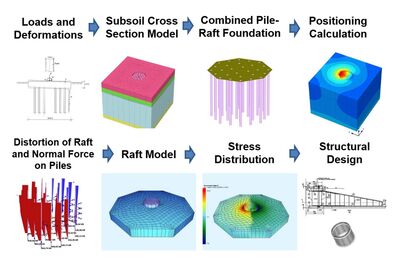

For some years now, projects related to tipping development (e.g. using wind turbines) have been increasingly processed. Special site foundations (eg combined pile and slab foundations) are developed here, tailored to the respective building site conditions. The work is done interdisciplinary in close cooperation with other departments within the GICON group of companies. The Repowering Windpark Klettwitz project is a prime example of this successful collaboration.

Our services:

Stability safety examinations / reports

- Establishment of exploration concepts, evaluations and evaluations of geotechnical field and laboratory investigations

- Stability calculations, slope assessments for wet and dry extraction and dumping and dumping, stability assessments and evidence, hazard assessments

- Variant studies for necessary security measures

- Development of concepts for the superstructure of industrial settling plants

- Checking / evaluating the reliability of the device and specifying safety distances / application limits

- Complex assessments of interior tipping with regard to settlement flow and liquefaction hazards as well as subsidence phenomena in the course of the groundwater recovery

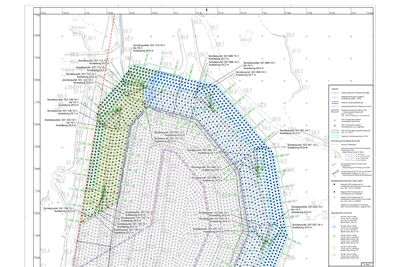

- Creation of compaction evidence as well as main and final reports for the termination of the mountain supervision

Mining rehabilitation planning and foundation consultancy for dump buildings or changed subsequent uses

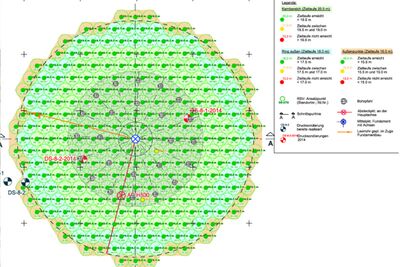

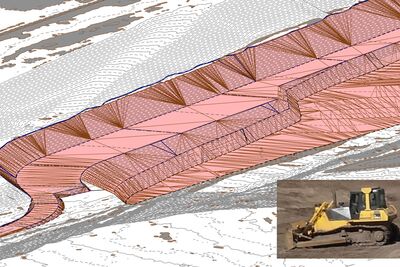

- 3-D modeling for required terrain profiling (using the InRoads program system, including as a basis for GPS-controlled device use)

- Foundation advice for dump buildings including dimensioning of necessary underground improvement measures

- Design of hidden dams to protect against possible settlement flow slippage (deep compaction, e.g. vibrating pressure compaction, vibrating plug compaction, falling weight compaction)

- Determining costs and quantities, cost-benefit analyzes, drawing up execution concepts and construction schedules

- Implementation planning for earthworks and compaction measures, including the related road construction

- Creation of service specifications and service descriptions

- Creation of operating plans according to the BBergG

Supervision, monitoring, supervision of construction work and aftercare

- Emergency services First backup of danger spots

- Property management or specialist construction management including acceptance of construction pits, piles and foundation blocks

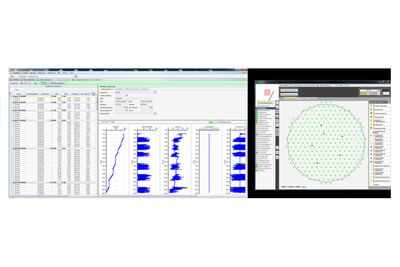

- Construction supervision, documentation and evaluation of geotechnical construction supervision and documentation of earthwork measures and deep compaction measures, among other things with the help of the in-house database system SCMS (compaction verification)

- Target-actual comparisons for terrain profiling, dimensional checks and quantity balances

- Specification of measurement concepts e.g. B. to monitor the development of pore water pressure, subsidence and vibrations (vibration velocity measurements)

- Evaluation and assessment of monitoring results (e.g. settlement and misalignment measurements for wind turbines on a tipping base

We work with the following special software:

- InRoads

- MicroStation (CAD software)

- FEM programs (including PLAXIS in cooperation with the TU Bergakademie Freiberg)

- Programs from GGU GmbH and DC-Software GmbH

-

Planning of necessary terrain profiling (terrain model for GPS caterpillar) -

Dimensioning and execution planning for required subsoil improvements -

Geotechnical engineers evaluating data with the in-house Soil Compaction Management System (SCMS) -

Special foundations on complicated subsoil -

Built-in driven piles -

After-use tipping with wind turbines

There are various options for the subsequent use of post-mining landscapes. GICON® has specialized in services that include the planning of wind farms in opencast mining areas as well as the flooding of old opencast mining holes including development into a lake landscape.

Subsoil investigations and compaction measures of the subsoil are crucial for a subsequent use in order to prevent slipping of the terrain. GICON® undertakes, for example, embankment explorations to determine the strength before and after compaction, the calculation of the stability, the planning of the securing measures including earthworks and the determination of specific compaction measures. Our in-house database (SCMS) makes it possible to produce the required compaction certificates in a quality-assured manner. This makes it easier to inspect the compaction quality and, if necessary, to identify faulty areas or insufficient compaction.

Landfills, post-mining landscapes and brownfield sites are generally inexpensive and exposed locations that are suitable for wind turbine development. Since the soils of these sites usually have a low bearing capacity down to greater depths, their development requires innovative solutions in foundation planning. GICON® has extensive experience in the exploration and consulting of such developments.

An innovative and executed specialized solution is the combined pile and raft foundation (KPP). With the KPP, piles are placed under the foundation slab in the subsoil, which has been improved by vibro-compaction, if required beforehand. The foundation slab is used for load transfer. The piles serve only as settlement brakes and are therefore taken into account in the design with their ultimate bearing capacity.

Advantages of the combined pile and raft foundation:

- Higher stiffnesses compared to canting due to the integration of the piles into the foundation slab

- Possibility to keep the foundation slab relatively small

- Guaranteed long-term stability and serviceability of the wind turbine

Our performance aspiration - A good solution for you!

Dipl.-Ing. Falk Rebbe

P: +49 351 47878-24

E: f.rebbe@gicon.de