Wind Engineering

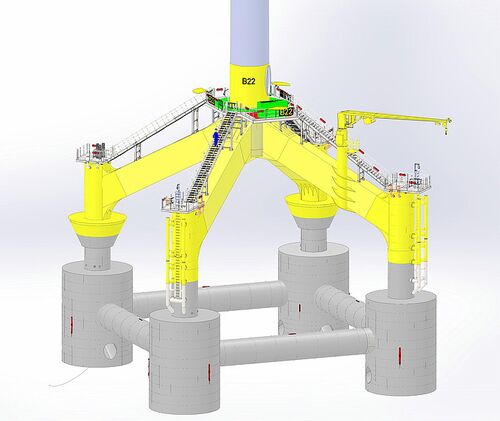

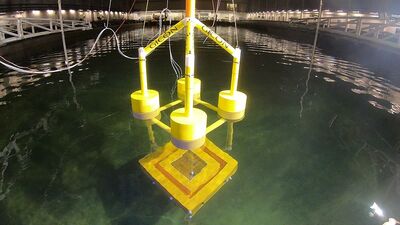

The department provides planning services for foundation structures in the offshore wind energy sector. The focus here is on the GICON®-SOF research project funded by the state of Mecklenburg-Vorpommern, the aim of which is to construct the first floating foundation with a 2 MW offshore wind turbine in Germany.

With the help of professional software support, the Offshore Wind Energy department carries out all planning services from the basic design to the design basis and thus creates the foundations for the further planning of the detailed design. The department coordinates other necessary services that other departments provide for the project, for example planning services for the subsoil, concrete construction, approval procedures or ecological issues.

Planning services for offshore structures

- project management research projects

- planning services for the design basis

- planning services for basic design

Further information

By using the GICON®-SOF in areas with high wind conditions at water depths of 45 to 350 meters and more, higher revenues can be generated than with fixed foundations.

A standardized system design can be used for each location, which reduces manufacturing costs. Differences in water depth are compensated for by the rope lengths alone, while the SOF design remains the same regardless of the water depth.

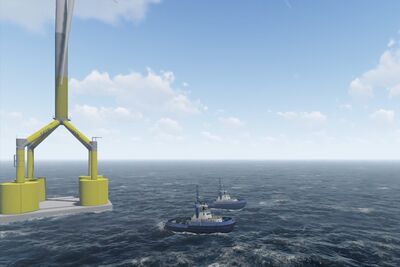

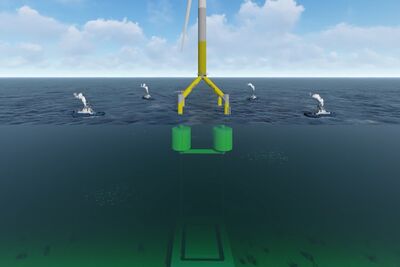

The foundation is manufactured and the turbine is assembled at a shipyard or in the harbor and is therefore independent of the weather. The system, including the turbine, is towed to the site on its own. This means that no expensive installation ships or jack-up platforms are required during installation. If the structures are no longer required one day, they are comparatively easy to dismantle at the end of their useful life.

The system can be completely replaced if necessary. Maintenance work can be carried out cost-effectively at a shipyard or in port.

An independent consulting institute determined a LCOE of 5 - 8 ct/kWh for the optimized design of the GICON®-SOF for a wind farm with 80 wind turbines with 6 MW each at a water depth of 80 m and a distance of 50 km to the mainland. The use in greater water depths and existing optimization potential will reduce these costs even further.

When offshore wind turbines are erected, pile driving the foundations into the seabed usually generates sound waves that can damage the hearing of marine life and cause behavioral changes. By refraining from ramming into the seabed, TLP is setting an example in terms of environmental protection and CO2 reduction.