Microalgae become resistant to biological contamination through targeted cultivation

A new research project entitled "Development of a biological process to control parasitic contaminants in industrial microalgae cultures" (KiM) aims to take the cultivation of microalgae to the next level of industrial use. In essence, this is a long overdue development that has been applied in agriculture for centuries and has led to various strategies to make plants resistant to pests and external influences. Practical trials in the GICON® Photobioreactor at the Central German Biosolar Center at Anhalt University of Applied Sciences will make an important contribution. The project is supported by the State Investment Bank of Saxony-Anhalt and is based on a grant from the European Regional Development Fund (ERDF). The project has a duration of 2 years (FKZ 2004/00101).

Nature does not know monocultures

Microalgae are an important source of raw materials for a future organic-based economy. In phototrophic cultivation, they convert more CO2 into biomass with the help of sunlight than plants and deliver several times higher biomass yields in relation to the area under cultivation.

In the new KiM research project, which GICON® will carry out together with the Anhalt University of Applied Sciences, the aim is to make the cultivation of microalgae less susceptible to contamination. GICON® project leader Dr. Martin Ecke explains the task: "The industrial production of microalgae biomass is carried out by phototrophic cultivation of non-sterile algae monocultures. These are extremely susceptible to biological contamination, comparable to monocultures in traditional agriculture. In agriculture, a variety of strategies have been developed over the centuries to limit the negative effects of potential harmful organisms, for example through crop rotation, the use of pesticides, or directed breeding of resistant species. Such methods are not yet available for the relatively young field of industrial microalgae cultivation."

Synthetic ecology shall lead to success

It is precisely these missing processes that are to be investigated and developed in the KiM research project. Synthetic ecology is expected to help. "Nature does not know monocultures, but only communities that help each other when there are different growth conditions," GICON®’s Head of the Biosolar Department Dr. Ecke describes the topic, "we want to use synthetic ecology to distribute different processes and reactions to different cells and thus make the microalgae culture more resistant. The goal is to develop a commercially-viable biological process for stabilizing industrial microalgae cultures!"

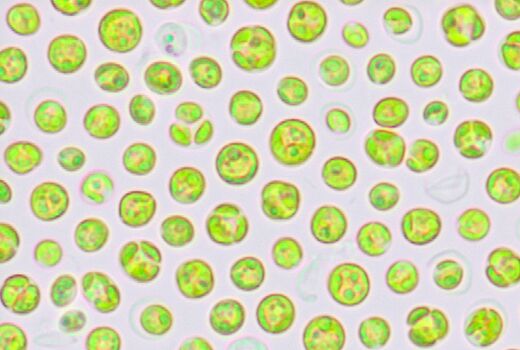

To achieve this goal, the first step is to identify microbiotic ecosystems and cultivate them in a targeted manner. By co-cultivating economically interesting microalgae with specifically-selected, potentially symbiotic bacteria, a second process step will result to protect the microalgae culture against externally-acting parasites.

GICON® takes over process engineering

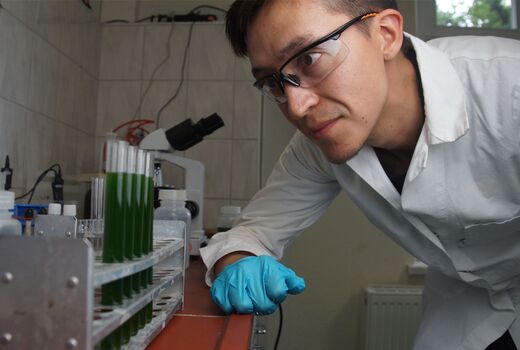

In the two-year KiM project, GICON® is responsible for process engineering development. The scientists of the Anhalt University of Applied Sciences are responsible for the biological investigation on population dynamics and further interactions of algae/bacteria mixed biocoenoses. All practical tests are to be carried out in the GICON® Photobioreactor at the Central German Biosolar Center. "Here we have the advantage," describes Dr. Ecke, "of being able to operate in either a sterile or a non-sterile manner and to precisely control a large number of process parameters (e.g. pH, process gas and nutrient composition)."

-

The research partner in the project is Anhalt University of Applied Sciences. In a first step, microbiotic ecosystems will be identified in the laboratory. | Source: Jan Claus/GICON® -

The aim of the project is to make microalgae cultures more resistant to the effects of contamination. | Source: Stefan Matthes/GICON® -

The project is supported by the Landesinvestionsbank Sachsen-Anhalt and is in its core a funding from the European Regional Development Fund (ERDF) - (FKZ 2004/00101) -